System creates a closed environment which promotes the growth and functionality of large 3D tissue mimetic structures, whether they are spheroids, organoids, bioprints and other aggregates. The clinostat principle, utilized by the ClinoStar 2 system is a technique uses rotation to mitigate the gravitational effects and is to generate 3D constructs from biological material. Control of reactors, temperature, CO₂ level, O₂ level (optional) and each of the 6 motors (independently) can be done remotely, using an intuitive software.

Key Features:

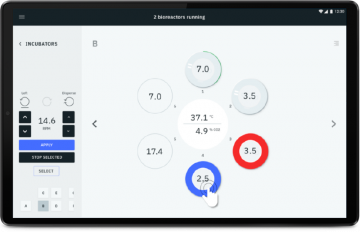

- Each reactor has an associated motor which can spin the reactor slowly. The speed of the motor can be precisely controlled individually using a tablet. The tablet can control multiple units.

- A fan is installed in the chamber for ventilation purposes to ensure a uniform environment within the chamber.

- For decontamination a UV-C beacon is placed in the chamber.

- 6 individual cameras allow monitoring of each bioreactor in real-time.

- The door has a push to open mechanism allowing the user to open the door with the elbow, so the hands of the user can be used for holding bioreactors.

- The unit has a small footprint and can be stacked up to 3 units high.

- Software application installed on the tablet can control up to 50 systems.