Products

“The Coy Anaerobic Chamber will provide considerable advantages in terms of atmospheric control and experimental scale.”

University of Vienna

“With the help of the COY hypoxic chamber we are able to biochemically study oxygen-sensitive proteins while preserving their enzymatic activity. The system is very easy to operate and scalable for even high-throughput experimental screens.”

Max Planck Research Group, Małopolska Centre of Biotechnology, Kraków, Poland

“Without the COY anaerobic chamber we could not work with strictly anaerobic methanogenic archaea.”

Faculty of Science, Masaryk University, Brno, Czech Republic

Rigid anaerobic chambers – COY laboratory products

Gloved Units

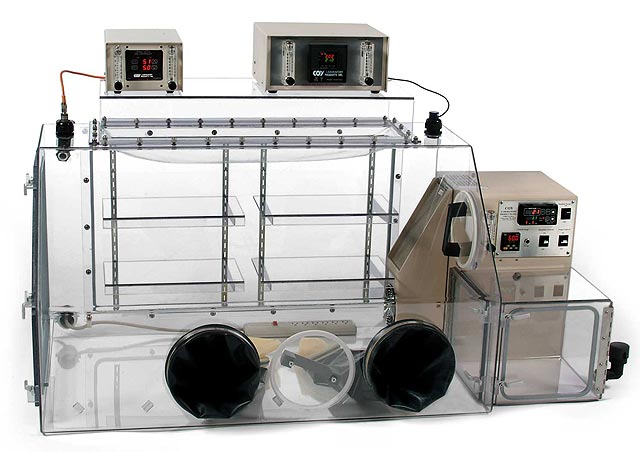

Rigid Anaerobic units can be manufactured from economical Polymer or the sturdy Aluminum.

The Aluminum units are ideal for labs with chemical resistance needs, due to the ability to upgrade the standard polycarbonate viewing screen to a Tempered Glass, and the Glove Port Panel to an Aluminum style. Aluminum Anaerobic Chambers also have the advantage to upgrade to a gloveless style.

The Polymer units are an easy and economical way to get started with an Anaerobic Chamber. Equiped with a purge only airlock these units are typically half the cost of the other style Anaerobic Chambers. It is important to keep in mind that while less exspensive to purchase it may cost more to operate due to the purge only application of the airlock, but in a low volume lab this may be just the unit for you.

The COY Anaerobic Chambers provide a strict anaerobic atmosphere of 0-5 parts per million (ppm) using a palladium catalyst and hydrogen gas mix of 5%. Air is circulated through a Fan Box which is designed to house the wire mesh container of catalyst called a Stak-Pak. The process of removing O2from the atmosphere can produce moisture so often times these Stak-Paks are filled with desiccant and stacked on top of the catalyst. The airlock allows sample transfer without changes to the internal atmosphere by equilibrating the O2 levels through a Vacuum and Purge procedure (purge only for the polymer units).

All units come equiped with this feature that allows the chamber to physically adjust to the users hands entering and exiting the glove box. No waiting for expensive electronics to compensate so there is no glove fight back.

The sleeves are manufactured from a durable neoprene with a seperate cuff that allows the attachment/replacement of and inexpensive glove within minutes.

More info at: https://coylab.com/products/anaerobic-chambers/anaerobic-chamber-rigid/

Documentation